Keep your home safe, warm and efficient—book a professional oil boiler service today.

Serving Shannon, Ennis, Newmarket-on-Fergus, Sixmilebridge, Bunratty, Clarecastle, Quin, Cratloe, and Limerick City.

Local winters in Clare and Limerick are damp, windy, and unforgiving—your boiler needs to be ready. With an annual service, you burn less oil, cut running costs, and avoid those sudden breakdowns on freezing nights.

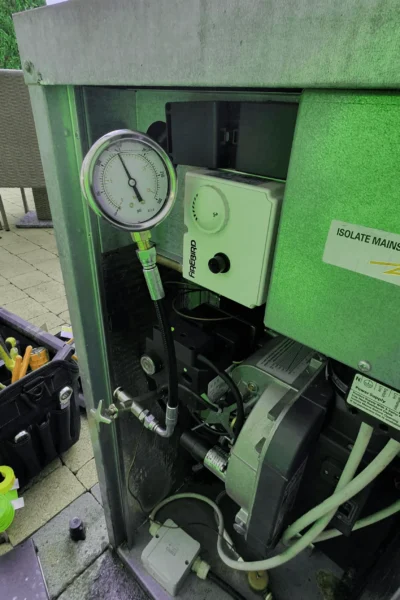

Choosing a local technician means faster response and the right parts on the van for Firebird, Grant, Warmflow and Riello boilers common in Shannon, Ennis, and nearby towns. That’s why so many of your neighbours already trust us every year.

Why service your oil boiler every 12 months?

Improve safety and reliability – reduce the risk of dangerous soot build-up, carbon monoxide leaks, or sudden lockouts in the middle of winter.

Lower fuel consumption and emissions – a clean burner and the right nozzle angle mean up to 10% savings on oil use and a greener home.

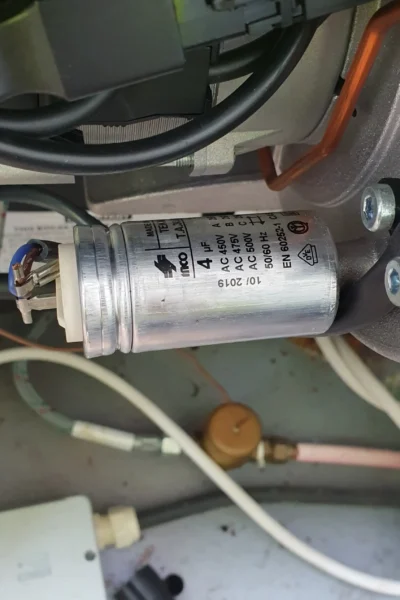

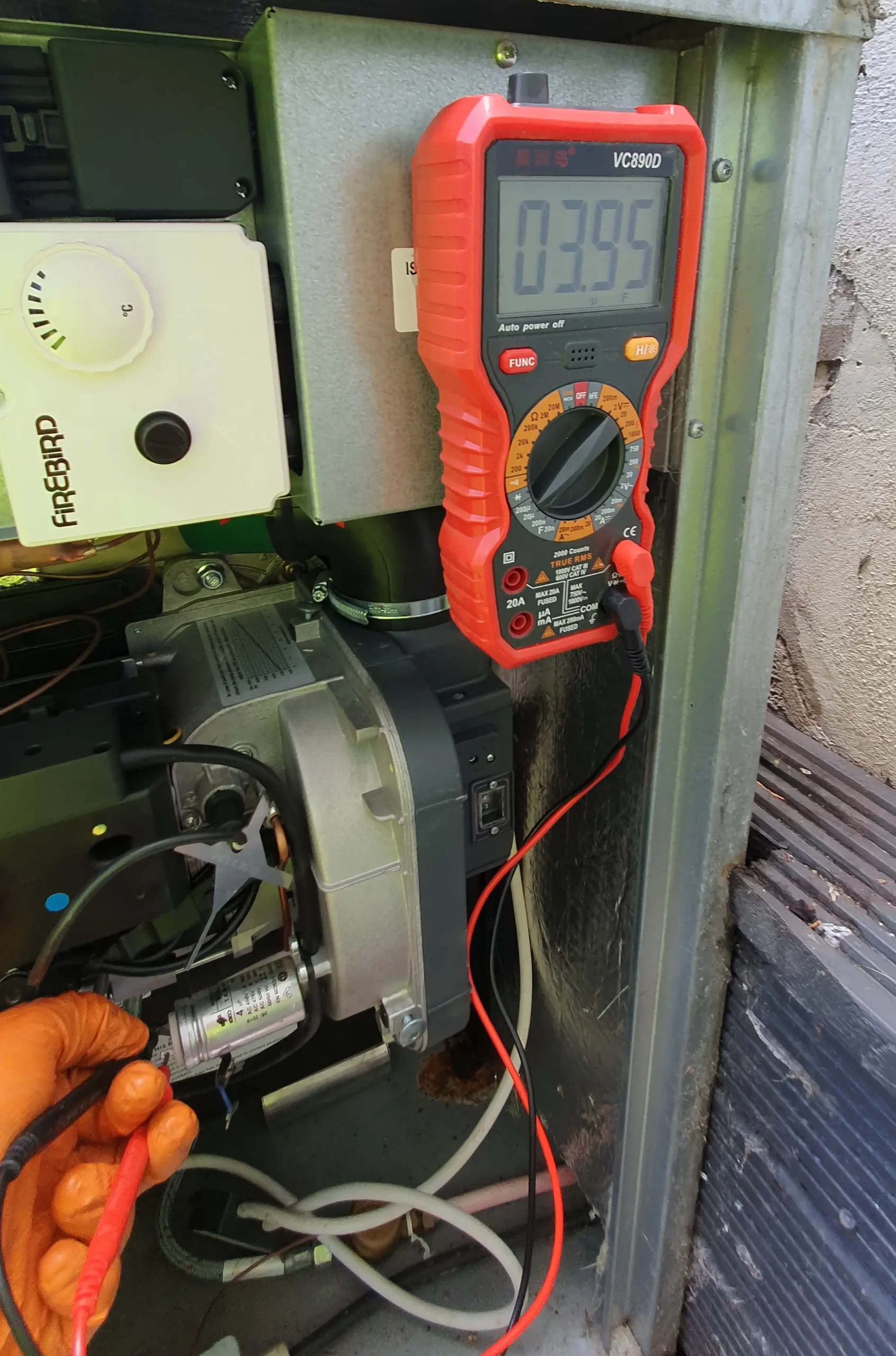

Catch small issues early – worn hoses, a weak capacitor, or a blocked baffle are cheap to fix now but expensive if left until breakdown.

Protect your warranty and insurance – most manufacturers and insurers require annual service records.

Extend the life of your boiler – regular cleaning and pressure checks prevent long-term damage and add years of service life.

Keep hot water and heating consistent – no more cold showers or radiators that only half-heat when the system is clogged.

Peace of mind – you get a dated service sticker, a full report, and a reminder for next year so you never have to worry about forgetting.

Brands & burners we work with

Boilers: Firebird, Grant (Vortex/Euroflame), Warmflow (Agentis/Utility), Stanley, others.

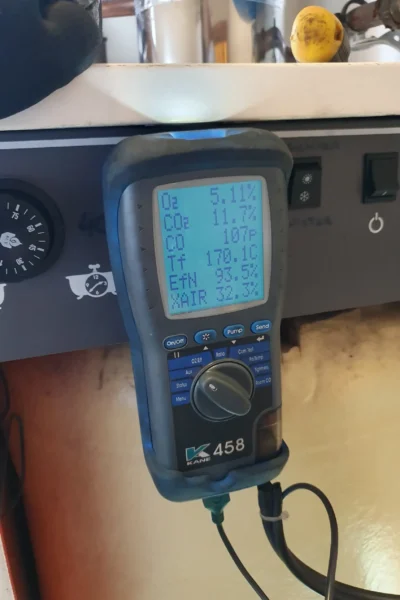

Burners: Riello RDB / RDB2 / RDB BX, Bentone, EOGB/ Sterling, Ecoflam.

Types of oil boilers we service

| Boiler type | Typical location | Key notes |

|---|---|---|

| Condensing, heat‑only | Indoor utility / outdoor module | Highest efficiency; needs condensate trap clean and baffle check |

| Non‑condensing, heat‑only | Older indoor/outdoor | Priority on chamber clean and soot management |

| Combi (oil) | Mainly indoor | Hot‑water plate exchanger care; scale prevention is critical |

| System | Indoor | Integrated expansion vessel and safety set |

| Boilerhouse / utility | Indoor utility space | Easy access for maintenance; check ventilation |

What’s included — our Standard Oil Boiler Service

Time on site: 60–90 minutes, typical.

What we do:

1. Visual check of casing, seals and insulation; check for corrosion/leaks

2. Flue inspection (leaks, corrosion, obstructions)

3. Oil tank, line and fire‑valve check; flexible hoses inspected

4. Replace oil nozzle (correct flow and spray angle)

5. Clean burner head, diffuser, blast tube; vacuum combustion chamber and baffles

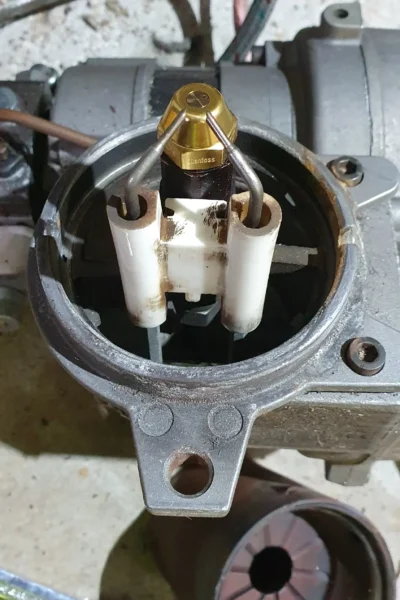

6. Clean and set electrodes (gap & position)

7. Clean/inspect photocell (flame sensor)

8. Test ignition transformer/starter and capacitor

9. Replace tank filter; bleed/prime oil line if required

10. Test and set pump pressure to manufacturer spec

11. Safety controls test (boiler/overheat thermostats, lockout)

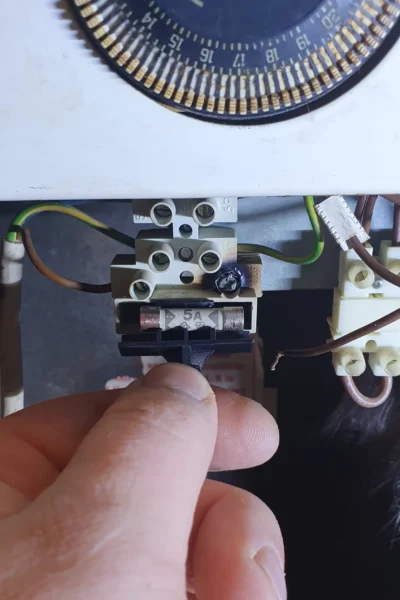

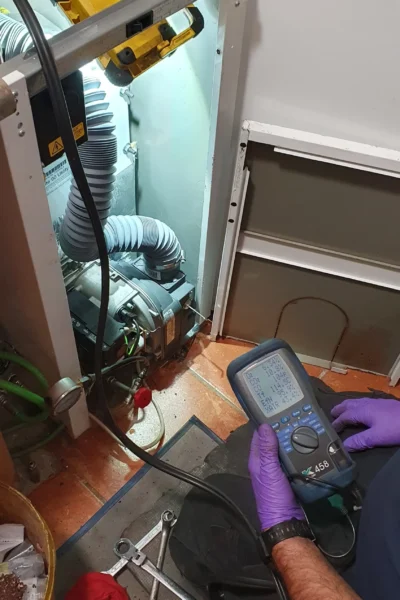

12. Electrical checks: wiring, fuses, earth continuity

13. Circulation checks (pump speed/noise/leaks); heating circuit test

14. Flue‑gas analysis & efficiency tune where applicable

15. Dated Service Report + Service Sticker + Next‑Due Reminder

Need more than a standard service? See Add‑ons and Diagnostics below.

Add‑ons you can choose

Burner strip‑down & rebuild (deep clean, seals, full recalibration)

Flexible hose replacement

Oil line & tank water test (water detection paste + treatment options)

Condensate trap clean (condensing models)

System inhibitor check & top‑up

Smart control check / timeclock optimisation

Standard Oil Boiler Service — from €150 (nozzle & tank filter included; parts beyond this quoted on site)

Emergency / breakdown call‑out — on request (priority slots available)

Pricing varies by boiler type, access, and parts required. You’ll always get a clear quote before work begins.

Digital Service Report (PDF) with a pass/fail checklist and actions taken

Photos of critical work (before/after)

Service Sticker on the boiler with date and next due

Next‑service reminder (12 months)

Report covers: flue, burner, oil line & hoses, safety controls, electrical checks, circulation checks, and (where applicable) flue‑gas readings & efficiency.

Technical note (for homeowners who like the details)

First of all, nozzle flow (GPH) and spray angle are matched to your specific burner and boiler (for example, Riello RDB on Firebird, Grant, or Warmflow).

In addition, the pump pressure is set to manufacturer specification and its stability is verified.

Next, we check the electrode gap and position, along with the photocell, ignition transformer, capacitor, and HV leads.

At the same time, the combustion chamber is inspected and vacuum-cleaned, and the baffles are thoroughly cleaned.

For safety, all control thermostats are tested and electrical earth continuity checks are carried out.

Finally, a flue-gas analysis is performed (where applicable) to optimise efficiency.

Optional upgrade: a full burner strip-down and rebuild can be completed, including a deep clean, new seals, and full recalibration.

1. Book — Сall, WhatsApp or use the Email

2. Service — a tidy, on‑time visit with parts stocked on the van

3. Report & handover — sticker, PDF report, and practical advice

Same‑/next‑day slots available in peak season.

FAQs

Typically 60–90 minutes, depending on access and boiler type.

Yes—these are part of our standard service. Any additional parts are discussed and agreed first.

Absolutely. Many local homes run Firebird/Grant/Warmflow outdoor models—we carry the common parts.

Yes. We set pump pressure, air, and electrodes to the manufacturer’s spec and verify stable combustion.

Yes—contact us to check availability today.

Yes—your sticker shows the due date and we’ll send a reminder near the anniversary.

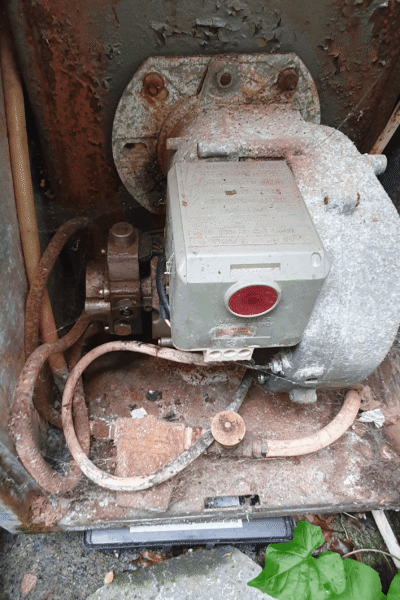

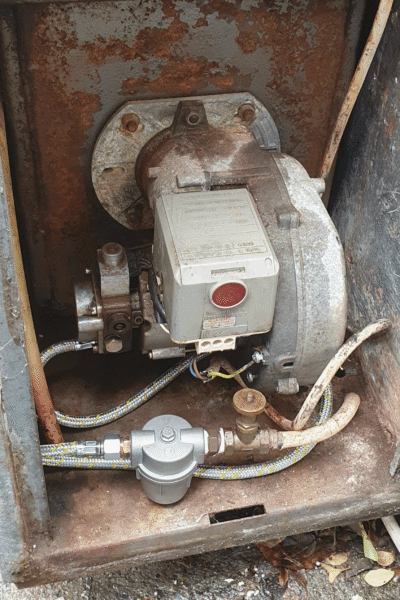

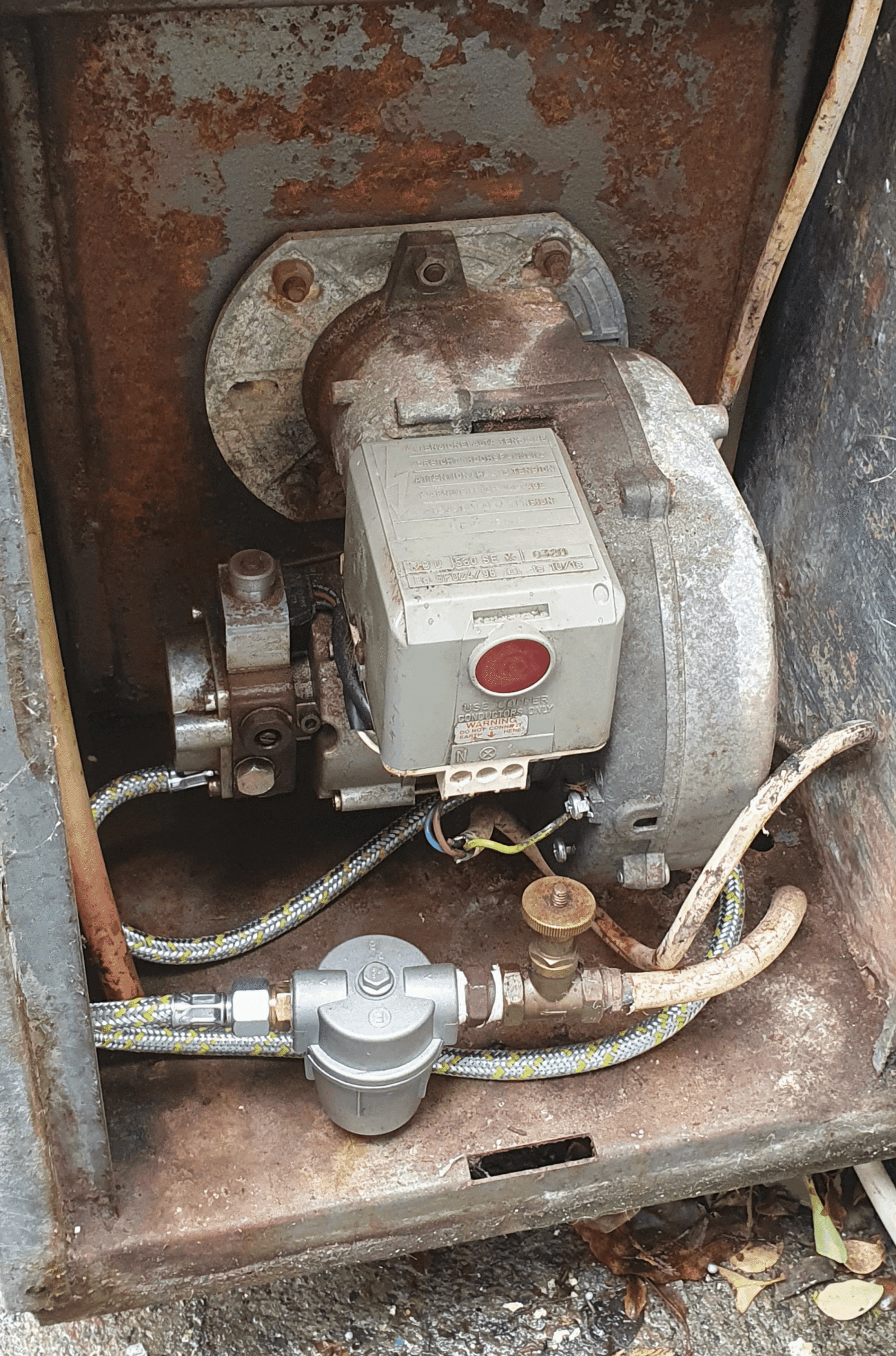

Before & After – See the Difference

A serviced boiler isn’t just cleaner inside—it runs quieter, burns oil more efficiently, and leaves no black soot or smoke. Our photos show the clear difference between a neglected burner and one that’s been properly cleaned, calibrated, and fitted with a new nozzle and filter. This way you can see exactly what our annual service delivers.

Common Oil Boiler Problems & How We Fix Them

| Problem (symptom) | Likely cause | Our solution |

|---|---|---|

| Boiler keeps locking out | Dirty photocell, worn nozzle, air in oil line | Replace nozzle, clean sensor, set pump pressure, bleed oil line |

| Black smoke / sooting | Wrong nozzle, poor air mix, blocked baffles | Chamber clean, new nozzle, adjust combustion air |

| Strong oil smell | Leaking hoses, filter seal failure | Replace hoses/seals, test fire valve |

| No hot water / poor heating | Blocked heat exchanger, faulty pump, control issue | Clean exchanger, test/replace pump, optimise controls |

| Noisy or rumbling burner | Incorrect electrode gap, weak capacitor/ignition | Reset electrodes, replace capacitor or igniter |

| Boiler not firing up | Faulty ignition, air in oil line, low pump pressure | Test ignition transformer, bleed line, reset pressure |

| Boiler leaking water or oil | Damaged seals, leaking hoses, faulty gaskets | Replace seals/hoses, pressure-test system |

| Boiler keeps switching off | Overheat thermostat trip, circulation fault | Check thermostats, bleed radiators, test pump |

| White smoke / steam | Condensate blockage, cracked baffles | Clear condensate trap, inspect baffles |

| Radiators not heating properly | Sludge, airlocks, weak circulation | System flush, bleed, pump check |

Serving Co.Clare, Co.Limerick – Shannon, Ennis & Limerick

-

- County Clare (Shannon, Ennis, Killaloe, Kilrush, Scarriff, Tulla, Newmarket‑on‑Fergus, Sixmilebridge, Bunratty, Clarecastle, Quin , Cratloe and more)

- County Limerick (including Limerick city and surrounding areas)

If you’re not sure whether we serve your area, just send us a message — we’ll do our best to assist.